When projects carry high stakes, the choices you make around joints, seals, and supports ripple through the whole build. Lifecycle-driven thinking keeps downtime short, budgets steady, and crews focused on work that moves the needle. We anchor this guide in field-tested steps that help you avoid costly rework and keep performance predictable. You’ll learn a practical sequence that makes inspections simpler and fixes rarer. If you buy through an Industrial Hardware Supplier, match specs to real loads, not just catalog lines, and log every assumption. Tying design intent to install details saves headaches later. Examples range from a retrofit in a cramped boiler room to a new loop in a light commercial plant. We emphasize pressure ratings, corrosion margins, and access for maintenance. The result is a consistent, safer path from planning to sign-off.

Define boundaries early and lock assumptions for installation success

Start with the service medium, temperature swings, and expected vibration, then map real constraints like ceiling height and access panels. We build a simple room-by-room checklist INDUSTRIAL HARDWARE SUPPLIER so every elbow, tee, and reducer is accounted for before procurement. Note gasket types and match them to corrosive exposure your system will face. Document hanger spacing now to prevent sag later. Confirm permit needs with facilities, and mark dates that can’t move. A clear scope reduces finger-pointing when surprises pop up.

Translate scope into a phased plan with measurable checkpoints. Stage effort by floor to limit disruptions and keep crews efficient. Build test points into the plan so quality never becomes an afterthought. Use color-coded drawings to keep supervisors aligned. When planning is visible, field teams deliver faster.

Choose materials and seals suited to environment demands

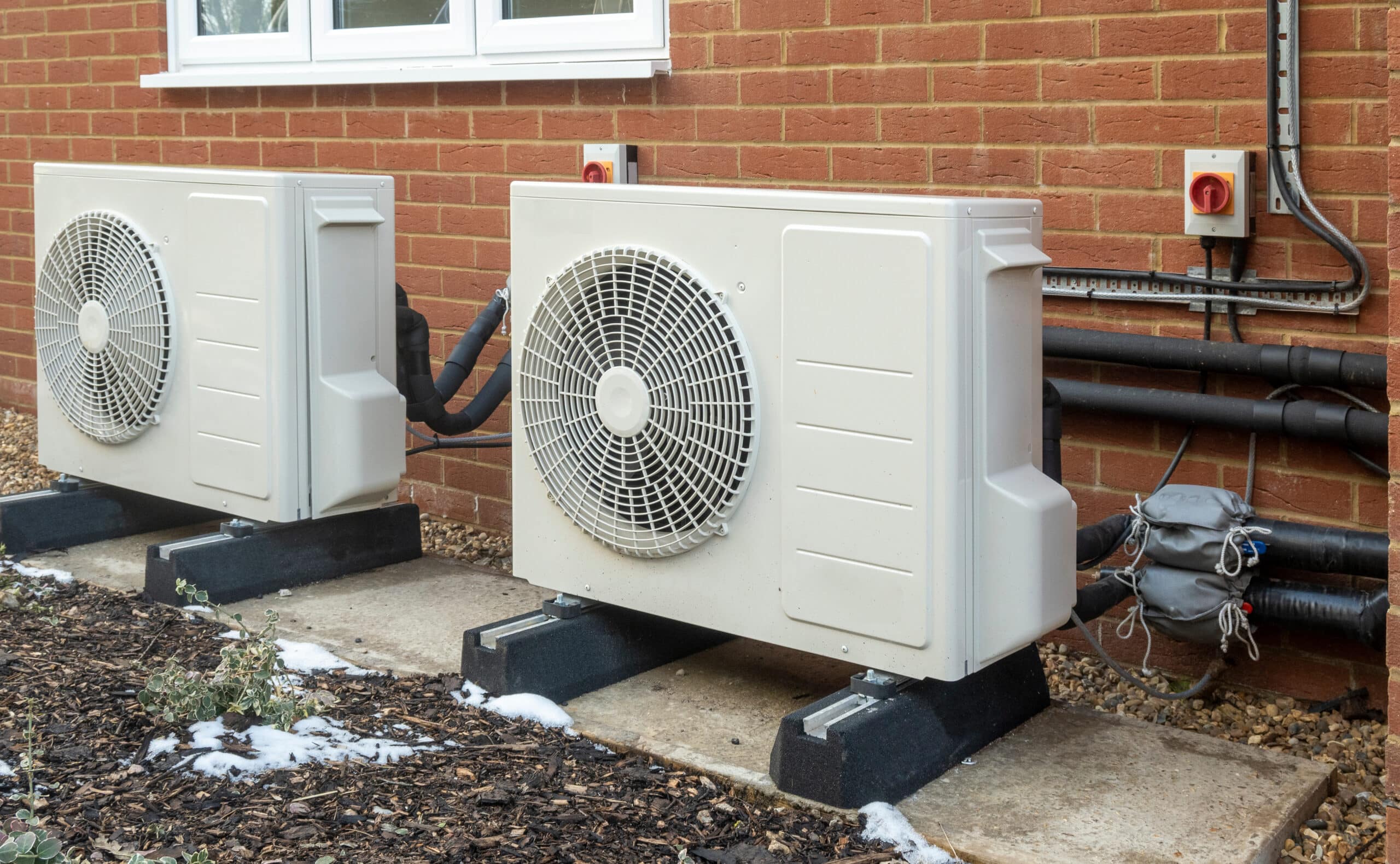

Start by pairing base metal to the fluid and temperature range; think stainless near chlorides and coated steel for moderate outdoor runs. We flag galvanic pairs and thread sealants on a single sheet industrial hardware supplier so buyers avoid mismatched sets under time pressure. Note elastomer grades where mixed materials meet, especially at pumps and heat exchangers. Select insulation compatible with jacket fittings. Choose a better seal to protect the harder-to-replace parts.

Label part numbers that truly matter, like valve end types and face-to-face lengths, and allow flexibility elsewhere. Relax aesthetics on hidden runs to focus spend where it counts. Archive data sheets for later maintenance. Tighter specs in the right places save time later. Picking components that match the environment prevents chronic issues.

Orchestrate workflow and staging to keep the job moving

Lay out a daily path that avoids stacking trades in the same aisle, and confirm lifting access for heavy assemblies. We draft a rolling two-week schedule Pipe Fittings & Flanges that pairs prefab windows with site rough-in, then we leave buffer for inspections. Prefit subassemblies on benches to shrink time at height. Bin by diameter to speed pulls. When tools and parts are close, crews gain hours.

Use check-in huddles at start and mid-shift, and make the punchlist visible. Flag rework instantly so nothing slips overnight. Block quiet times for testing. Short feedback loops cut waste. Cadence and buffers make delivery predictable.

Control leak risk with verification that fits real-world conditions

Adopt a three-point check: fit-up, fastener torque, and post-test recheck after thermal cycles. We use calibrated wrenches and a simple stamp system INDUSTRIAL BOLTS AND NUTS to mark each joint as it passes a step. Torque patterns matter on raised-face flanges in variable conditions. Note any re-torque so trends surface early. A quick photo record beats memory on shift change.

Tie inspection to risk, not just habit, and focus on high-pressure or high-consequence runs. Scale effort to hazard, not length to use time wisely. Hydrotest with proper blinds to protect seals. Fastener health decides whether a seal holds or weeps. Quality is a habit you can schedule.

Sustain service life with maintenance that technicians actually follow

Design with future access in mind; a valve you can’t reach is a failure waiting. We add clear tags and protected log sheets near major joints Industrial Hardware Supplier so techs can record readings without hunting. Pick supports that allow micro-adjusts to reduce fatigue. Spare gaskets ride in labeled bins. If care is easy, it actually happens.

Build a seasonal routine: spring torque checks, fall seal scans, and quick visual surveys after thermal spikes. Train facility teams with brief refreshers by equipment. Track leak calls and spot patterns to catch slow failures. Replace cheap wear items on a schedule, not a crisis. Consistent attention keeps systems quiet.

Vet vendors and questions to fit the job and culture

Seek partners who show test results, not just talk, and who welcome field audits. We favor clear quotes with delivery windows and alternates listed Industrial Hardware Supplier so substitutions never surprise your crew. Ask how they handle rushes during peak season. Review sample joints together. Good partners make your plan sturdier.

Confirm communication habits and escalation paths before anything goes sideways. Who picks up after hours should be on one page. Share drawings early for takeoffs to avoid churn. Fit matters as much as price. Alignment on expectations turns "vendor" into "team".

Conclusion

From front-loaded scoping to steady maintenance, the path to consistent performance is a chain of small, deliberate steps. We balanced environment-ready materials, predictable workflows, and measured quality checks to keep leaks rare and schedules sane. Fold in vendor fit and practical service access, and the system stays stable under real-world pressures. Choose wisely, verify often, and your crews will spend more time building and less time fixing.